Khoom piav qhia

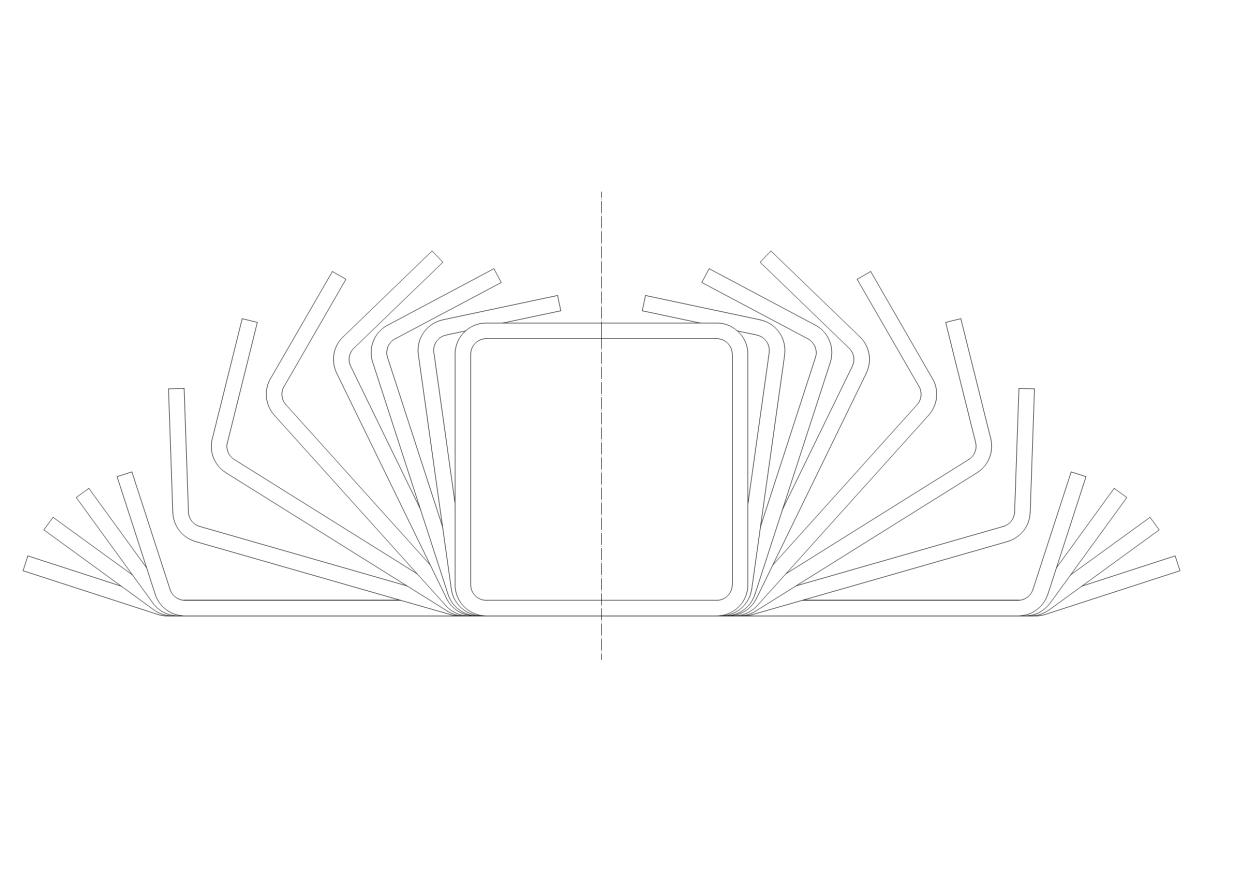

Lub square lossis duab plaub yog tsim tawm ua ntej lub raj vuam.

Txheej Txheem Flow

Hlau Chev → Uncoiling → Flattening/Leveling → Shear & End Cutting → Coil Accumulator → Forming → Vuam → Deburring → Dej Coiling → Sizing → Straightening → Txiav →Lub rooj khiav

Qhov zoo

1.piv nrog puag ncig rau hauv square & duab plaub txoj kev tsim, txoj kev no yog qhov zoo dua rau cov duab ntawm cov hlaws, piv txwv li, ib nrab txoj kab uas hla ntawm lub puab tsaig yog me me, thiab lub brim yog tiaj tus, sab yog tsis tu ncua, zoo meej zoo ntawm lub raj.

2.Thiab tag nrho cov kab load yog tsawg, tshwj xeeb tshaj yog cov sizing seem.

3.Qhov dav ntawm steel sawb yog li 2.4 ~ 3% me dua li ntawm puag ncig rau hauv square / duab plaub, nws tuaj yeem txuag tau tus nqi ntawm cov khoom siv raw.

4.Nws siv txoj kev khoov ntau txoj hauv kev, zam lub axial quab yuam thiab sab abrasion, txo cov txheej txheem thaum ua kom zoo, lub sijhawm no nws txo cov hluav taws xob khib nyiab thiab cov menyuam abrasion.

5.Nws tau txais kev sib xyaw ua ke ntawm cov menyuam feem ntau ntawm cov khoom siv, nws pom tau tias ib txheej ntawm cov menyuam tuaj yeem tsim txhua qhov ntau thiab tsawg ntawm square / square raj nrog cov kev qhia tshwj xeeb, nws txo cov khw muag khoom ntawm cov menyuam, txo tus nqi txog 80% ntawm cov menyuam, ceev lub bankroll turnover, luv lub sij hawm ntawm cov khoom tshiab tsim.

6.Tag nrho cov menyuam yog cov sib koom ua ke, tsis tas yuav hloov cov chais thaum hloov lub raj loj, tsuas yog kho txoj haujlwm ntawm cov menyuam los ntawm lub cev muaj zog lossis PLC, thiab pom tau tias tag nrho tsis siv neeg tswj;nws zoo heev txo cov menyuam hloov lub sijhawm, txo cov kev siv zog, txhim kho kev tsim khoom.

Post lub sij hawm: Oct-25-2021