Product Description

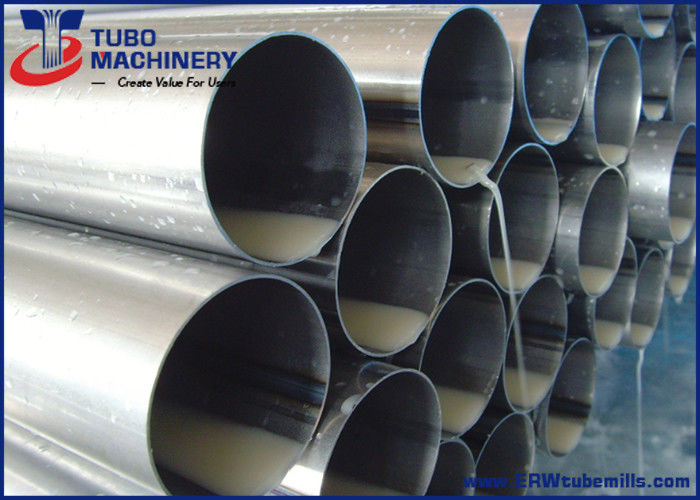

Peb Cov Txias txiav tuaj yeem ncav cuag qhov siab (± 1.0mm) thiab cov yeeb nkab kawg yog du tsis muaj burr.Ob qho tib si zoo hauv cov khoom siv carbon & stainless hlau.

Khoom Paub meej

1. Automated txiav inline.

2.LCD kov npo.

3.Kev kub ceev thiab siab precision txiav.

4.Excellent txiav nto, tsis muaj burrs & txuag nqi.

Daim ntawv teev npe

| Qauv NO. | Steel yeeb nkab txoj kab uas hla (mm) | Steel yeeb nkab thickness (mm) | Max ceev (M / min) |

| Φ25 | Φ6-30 | 0.3-2.0 | 120 |

| Φ32 | Ib 8-38 | 0.3-2.0 | 120 |

| Φ50 | Φ20-63.5 | 0.6-2.5 hli | 100 |

| Φ76 | Ib 25-76 | 0.8-3.0 | 100 |

| Φ89 ua | Φ25-105 | 0.8-4.0 Nws | 80 |

| Ib 114 | Φ50-130 | 1.2-5.0 Nws | 60 |

| Ib 168 | Φ80-168 | 2.0-6.0 Nws | 60 |

Cov Cheebtsam tseem ceeb ntawm cov khoom siv

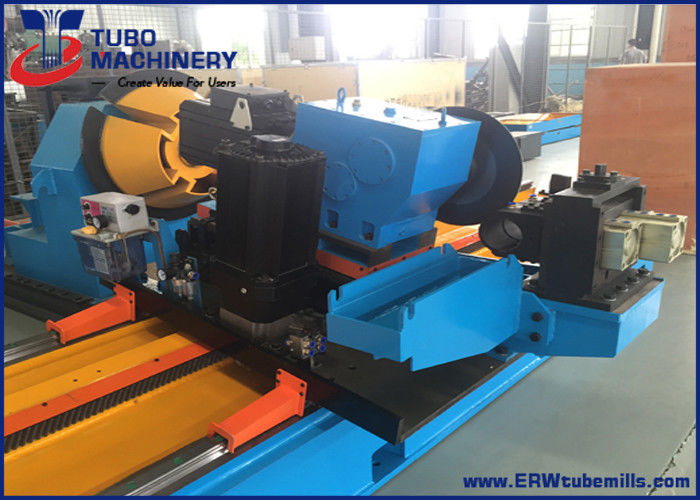

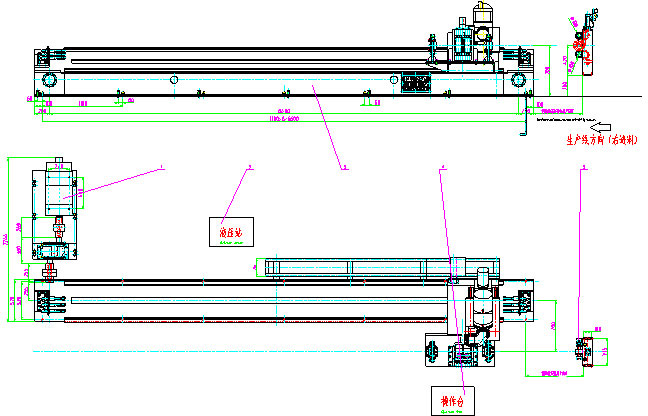

1. lub ntsiab tshuab

2. hydraulic system

3. tus tswv tsev tseem ceeb ntawm kev txiav tawm

4. Lub rooj ua haujlwm (tsim hluav taws xob tswj txee: yuav tsum tau nruab rau hauv chav tswj hluav taws xob)

5.speed ntsuas cov menyuam

Specification

| Technical Parameters | ||

| Khoom siv | Carbon Steel | |

| Tensile zog | <400N/mm2 | |

| Cov yeeb nkab loj | Round yeeb nkab | 48 ~ 127 hli |

| Square yeeb nkab | 40 * 40 ~ 100 * 100 hli | |

| Rectangle yeeb nkab | 50 * 30 ~ 140 * 60mm | |

| Thickness | 1.0 ~ 5.0 hli | |

| Txiav Ntev | <32 Kev hloov kho tsis tu ncua | |

| Ceev | Max 80m / min | |

| Servo / AC Tsav | Tsav Tsav | YASKAWA/SIEMENS |

| Feeding Tsav | YASKAWA/SIEMENS | |

| Txiav Tsav | YASKAWA/SIEMENS | |

| Saw Blades | HSS/TSI | |

1. Q: Koj puas yog cov chaw tsim khoom?

A: Yog, Peb yog cov chaw tsim khoom.Ntau tshaj 15 xyoo R & D thiab Kev Tsim Khoom.Peb siv ntau tshaj 130 CNC machining equipments los lav peb cov khoom zoo meej.

2. Q: Cov nqe lus them nqi twg koj txais?

A: Peb hloov pauv ntawm cov nqe lus them nqi, thov hu rau peb kom paub meej.

3. Q: Cov ntaub ntawv dab tsi koj xav tau los muab cov lus hais?

A: 1. Lub zog siab tshaj plaws ntawm cov khoom siv,

2.Tag nrho cov yeeb nkab qhov ntau thiab tsawg (hauv mm),

3. Phab ntsa thickness (min-max)

4. Q: Koj qhov zoo yog dab tsi?

A: 1. Advanced pwm sib koom siv tshuab (FFX, Direct Forming Square).Nws txuag tau ntau qhov peev txheej.

2. Kev hloov pauv ceev ceev tshaj plaws los ua kom cov zis ntau ntxiv thiab txo kev siv zog.

3. Ntau tshaj 15 xyoo R&D thiab Kev Tsim Khoom.

4. 130 CNC machining equipments los lav peb cov khoom zoo meej.

5. Customized Raws li cov neeg siv khoom xav tau.

5. Q: Koj puas muaj kev txhawb nqa tom qab muag?

A: Yog, peb muaj.Peb muaj 10-tus neeg-kev cob qhia thiab muaj zog installation pab neeg.

6.Q: Ua li cas txog koj qhov kev pabcuam?

A: (1) Ib xyoos lav.

(2) Muab cov khoom seem rau lub neej ntawm tus nqi.

(3) Muab kev txhawb nqa Video technical, Field installation, commissioning thiab kev cob qhia, kev txhawb nqa online, Cov Kws Ua Haujlwm muaj rau kev pabcuam tshuab txawv teb chaws.

(4) Muab kev pabcuam rau kev kho vaj tse, kho dua tshiab.