Kev piav qhia ntau lawm

Cov cuab yeej siv tshwj xeeb no yog siv los ua cov khoom siv high-frequency ncaj seam welded yeeb nkab thiab cov yeeb nkab square thiab cov yeeb nkab tshwj xeeb.Cov khoom siv muaj pes tsawg leeg yog los ntawm uncoiler mus rau qhov ntev txiav txiav .Rolling ceev tuaj yeem ua tau raws li qhov tsim nyog ntawm cov yeeb nkab txoj kab uas hla thiab phab ntsa thickness.

| Khoom | WeldedYeeb Nkab Tshuab |

| Khoom siv tau | HR / CR, Tsawg Carbon Steel Sawb Chev, Q235, S235, Gi Strips. σb≤550Mpa,σs≤235MPa |

| Cov yeeb nkab txiav Length | 60.0 ~ 12.0m |

| Ntev Ntev | ± 1.5 hli |

| Nto | Nrog Zinc Txheej lossis tsis muaj |

| Ceev | Max.Ceev: ≤120m / min (tuaj yeem kho raws li cov neeg siv khoom xav tau) |

| Lwm tus | Tag nrho cov yeeb nkab yog high zaus welded |

| Khoom siv ntawm cov menyuam | Cr12 |

| Nyem yob | H13 |

| Scope ntawm welded yeeb nkab khoom | Hydraulic ob-Mandrel un-coiler |

Daim ntawv thov:GI, Kev Tsim Kho, Automotive, General Mechanical Tubing, Rooj Tog, Kev Ua Liaj Ua Teb, Chemistry, Roj, Roj, Conduit, Kev Tsim Kho.

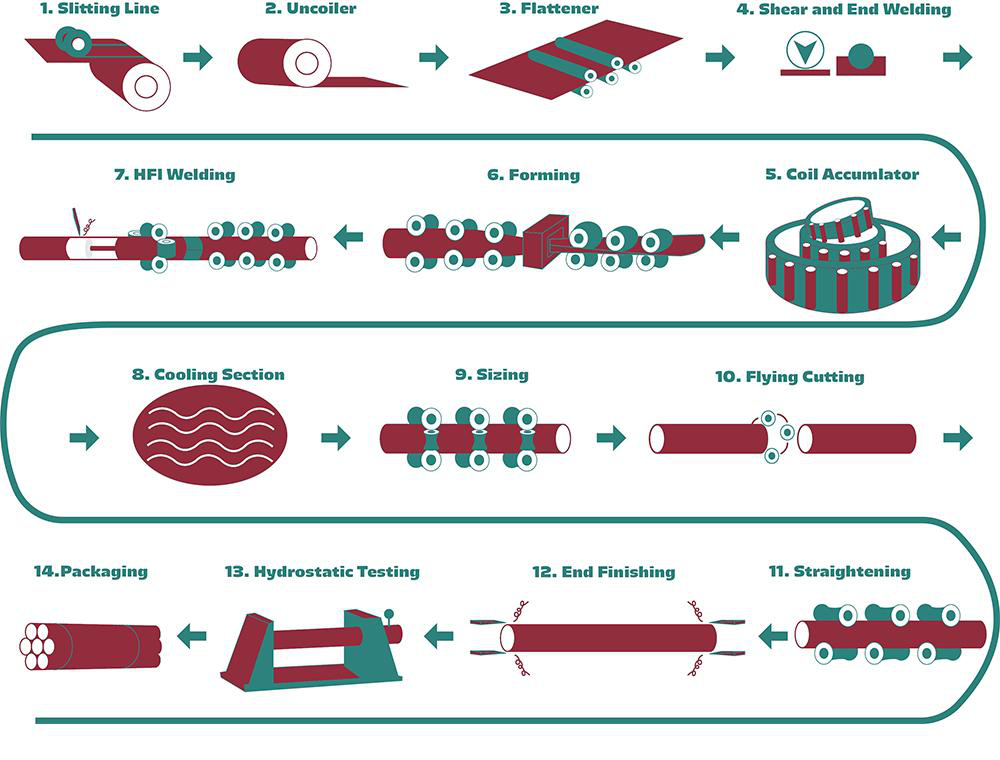

Txheej Txheem Flow

Hlau Chev→Ob-arm Uncoiler→Shear thiab End Txiav & Vuam→Coil Accumulator→Kev sib sau (Flattening Unit + Main Tsav Tsheb + Lub Tsev Ua Haujlwm + Cov Lus Qhia + Lub Tsev Muaj Zog Induction Welding + Squeeze Roller)→Deburring→Dej Txias→Sizing & Straightening→Flying Saw Txiav→Tube Conveyor→Ntim→Warehouse Cia

Qhov zoo

1.High Production Efficiency.

2. High precision

3.High Strength, Lub tshuab ua haujlwm ruaj khov ntawm kev kub ceev, uas txhim kho cov khoom zoo.

4.Low Defective khoom nas

5.Txuag Roller Chaning Sijhawm

6.Txuag invetment ntawm rollers

Specification

| Raw Khoom | Coil Khoom | Cov pa roj carbon tsawg, Q235, Q195 |

| Dav | 35mm-120mm | |

| Thickness | 0.5mm-2.5 hli | |

| Coil ID | φ450-φ520mm | |

| Coil OD | Max φ1200 hli | |

| Coil Nyhav | 1.0-1.5Tons | |

| Muaj Peev Xwm Ntau Lawm | Round yeeb nkab | 8mm-32 hli |

| Square & Rectangular Yeeb Nkab | 8 * 8 - 25 * 25mm | |

| Phab ntsa Thickness | 0.5-2.0mm (Round Yeeb Nkab) | |

| Ceev | Max.120m / min | |

| Cov yeeb nkab ntev | 3 m-12 m | |

| Cov xwm txheej ua haujlwm | Lub zog muaj zog | 380V, 3 theem, 50Hz (nyob ntawm cov chaw hauv zos) |

| Tswj fais fab | 220V, ib theem, 50 Hz | |

| Qhov loj ntawm tag nrho cov kab | 50 x 5m(L* W) | |

1. Q: Koj puas yog cov chaw tsim khoom?

A: Yog, Peb yog cov chaw tsim khoom.Ntau tshaj 15 xyoo R & D thiab Kev Tsim Khoom.Peb siv ntau tshaj 130 CNC machining equipments los lav peb cov khoom zoo meej.

2. Q: Cov nqe lus them nqi twg koj txais?

A: Peb hloov pauv ntawm cov nqe lus them nqi, thov hu rau peb kom paub meej.

3. Q: Cov ntaub ntawv dab tsi koj xav tau los muab cov lus hais?

A: 1. Lub zog siab tshaj plaws ntawm cov khoom siv,

2.Tag nrho cov yeeb nkab qhov ntau thiab tsawg (hauv mm),

3. Phab ntsa thickness (min-max)

4. Q: Koj qhov zoo yog dab tsi?

A: 1. Advanced pwm sib koom siv tshuab (FFX, Direct Forming Square).Nws txuag tau ntau qhov peev txheej.

2. Kev hloov pauv ceev ceev tshaj plaws los ua kom cov zis ntau ntxiv thiab txo kev siv zog.

3. Ntau tshaj 15 xyoo R&D thiab Kev Tsim Khoom.

4. 130 CNC machining equipments los lav peb cov khoom zoo meej.

5. Customized Raws li cov neeg siv khoom xav tau.

5. Q: Koj puas muaj kev txhawb nqa tom qab muag?

A: Yog, peb muaj.Peb muaj 10-tus neeg-kev cob qhia thiab muaj zog installation pab neeg.

6.Q: Ua li cas txog koj qhov kev pabcuam?

A: (1) Ib xyoos lav.

(2) Muab cov khoom seem rau lub neej ntawm tus nqi.

(3) Muab kev txhawb nqa Video technical, Field installation, commissioning thiab kev cob qhia, kev txhawb nqa online, Cov Kws Ua Haujlwm muaj rau kev pabcuam tshuab txawv teb chaws.

(4) Muab kev pabcuam rau kev kho vaj tse, kho dua tshiab.